广州市银标贸易有限公司

联系人:赖先生

手机:13922125860

固话:+86-20-23830796 23830403

传真:+86-20-34637699

网址:www.gzyinbiao.com

邮箱:laiqiangping2010@163.com

地址:广州市番禺区钟村镇钟荣路1号致业科技中心A栋3楼AS388#

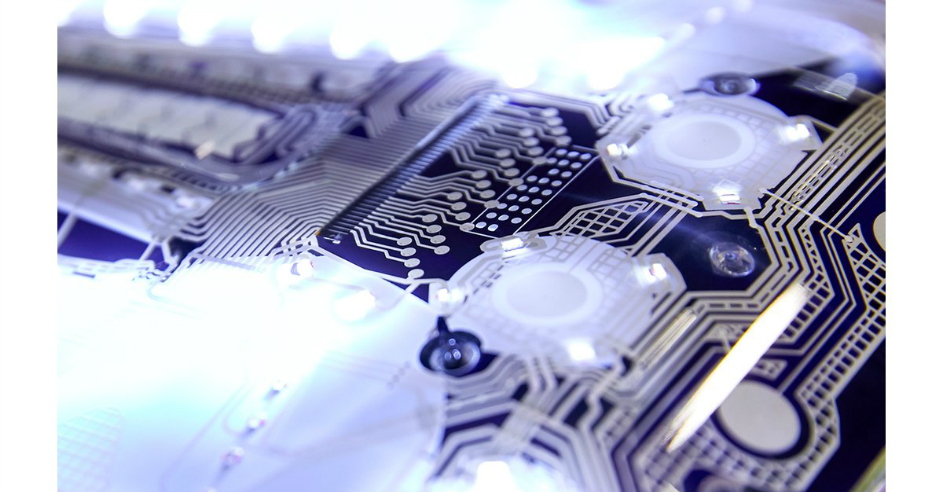

“注塑成型结构电子产品”或IMSE。 开发了一种3D塑料打印方法,该方法将电子功能融合到物体表面,几乎可以将任何材料转换为用户界面,而无需按钮或其他传统控件。突破性的设计已被汽车工业迅速采用,但T拥有更大的野心,将其制造工艺应用于几乎所有类型的连接对象。 我们正在制造薄的,3D的,重量轻的,并具有功能性的塑料零件。” Keranen说。 “因此,包装盒不再与功能分开。过程非常不同。人们需要花时间来学习和理解它。” 该公司已开发出一种称为“注塑结构电子产品”或IMSE的制造工艺。 公司四步过程的前两个部分涉及使用相当标准的电子打印方法,该方法可创建二维纸,并在其上印有如下所示的电路: 然后,该板将经历称为“热成型”的过程,从而可以将其成型为三维设计。要使用此过程,已印刷的塑料,材料和电路必须能够拉伸并承受热量。结果如下: 从那里开始,对组件进行注塑成型,使其可以用多种材料覆盖,包括木材或塑料:

“injection molded structural electronics” or IMSE.

has developed a method of 3D plastics printing that fuses electronic functions into the surface of objects, allowing just about any material to be transformed into a user interface without the need of buttons or other traditional controls. The breakthrough design has been rapidly adopted by the automotive industry but T has broader ambitions to bring its manufacturing process to just about every category of connected object.

We are making plastic parts that are thin, 3D, and lightweight and that include the functionality,” says Keranen. “So the box is no longer separate from the functionality. The process is very different. And it’s going to take time for people to learn it and understand it.”

The company has develop a manufacturing process called “injection molded structural electronics” or IMSE.

The first two parts of the company’s four-step process involve using fairly standard electronic printing methods that create two-dimensional sheets with circuits imprinted on them that look like this:

That sheet then undergoes a process called “thermoforming” that allows it to be shaped into a three-dimensional design. To use this process, the plastic, materials, and circuits that had been printed need to be able to stretch and withstand the heat. The result then looks like this: